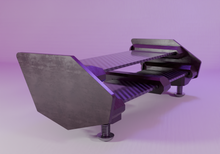

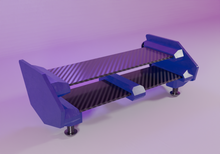

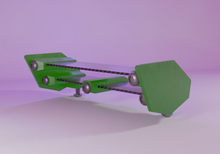

Combining carbon fiber plates with plastic structures offers a range of benefits, especially for parts like RC car wings, drones, and other performance-oriented components. Here are the key benefits:

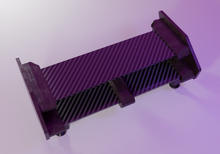

- Strength and Flexibility: Carbon fiber provides rigidity and high tensile strength, while plastic allows flexibility, absorbing impacts and reducing the likelihood of cracking or permanent deformation.

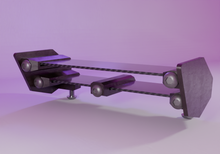

- Lightweight Durability: Carbon fiber is exceptionally strong yet lightweight, reducing the overall weight without sacrificing durability. This allows for better speed, control, and performance in applications like racing.

- Enhanced Shock Absorption: Plastic's flexibility can absorb shocks effectively, working as a buffer that helps reduce wear on the carbon fiber plates in high-stress situations.

- Cost Efficiency: Hybrid structures can be more cost-effective than using carbon fiber alone, as plastic is typically less expensive. This approach maximizes performance while minimizing costs.

- Improved Aerodynamics: Carbon fiber’s smooth surface and structural rigidity enable better aerodynamic performance, while the plastic structure can be molded into complex shapes for improved airflow and reduced drag.

- Easy to Modify and Replace: In hybrid designs, the plastic portions can often be easily modified or replaced if damaged, extending the lifespan of the more costly carbon fiber components.

- Customizable Design: The combination allows for intricate, precise designs where strength is needed (carbon fiber plates) and flexibility is useful (plastic structures), making it ideal for applications requiring tailored functionality.

This hybrid design offers a balanced solution for high-performance needs, blending the best characteristics of both materials.

Comparing Weights Video... https://www.instagram.com/p/DB4H8bxxItR/